In this guide, we explain what pallet wrap is, how it is used, the types available, and why thickness matters. We also look at machine pallet wrap versus hand pallet wrap, and pre-stretched versus conventional wrap.

Table of Contents

What is Pallet Wrap?

Pallet wrap is a thin stretch film made from plastic. It is wrapped tightly around goods or boxes on a pallet to hold them in place. Pallet wrap keeps items safe during storage and transport. It also protects products from dust, dirt, and damage caused by movement.

Types of Pallet Wrap

There are two main ways to make pallet wrap: cast wrap and blown wrap.

Cast Wrap

Cast wrap is made by spreading the plastic into thin sheets. It is smooth, strong, and easy to stretch. Cast wrap is great for hand wrapping because it is easy to handle.

Blown Wrap

Blown wrap is made by blowing the plastic into a tube shape. It is stronger and stickier than cast wrap, so it holds pallets tightly. Blown wrap works well for machine wrapping and heavy loads.

Hand Wrapping vs Machine Wrapping

Hand Wrapping

Hand wrap is lighter and easier to pull, making it ideal for smaller operations or when only a few pallets need to be secured. Workers can wrap pallets quickly without the need for a machine, keeping costs low and offering flexibility in different environments.

Hand wrap is usually made from cast film, as it is quieter to use, provides good clarity for scanning barcodes, and is easier to handle.

However, it may not provide the same load-holding power as machine wrap for heavier or unstable pallets.

Machine Wrapping

Machine wrap is stronger and can stretch further, making it more efficient for high-volume operations.

It is specifically designed for wrapping many pallets quickly in busy warehouses, improving productivity and consistency. Using a machine also reduces worker strain and helps achieve a more uniform wrap compared to hand application.

Machine wrap can be made from cast or blown film:

Cast film offers clarity and smooth unwinding, making it easier to use for lighter to medium loads.

Blown film provides higher puncture resistance and stronger load-holding power, which is better for heavier, irregular, or sharp-edged pallets.

Machine wrapping not only improves load security but can also reduce film waste due to controlled stretch settings, making it a more sustainable option in the long run.

| Feature | Hand Wrap️ | Machine Wrap |

|---|---|---|

| Ease of Use | Simple to apply manually; no machine needed | Requires a pallet wrap machine |

| Speed | Slower best for low-volume wrapping | Much faster - ideal for high-volume operations |

| Strength | Moderate - suited to lighter, stable loads | Higher - suited to heavier or unstable loads |

| Film Type | Usually cast film for ease of handling and clarity | Cast (clarity & smoothness) or blown (strength & resistance) |

| Cost | Lower upfront cost; may use more film over time | Higher upfront (machine), but saves film in the long run |

| Consistency | Depends on worker technique | Uniform and consistent every time |

| Sustainability | Can produce more waste if over-applied | Less waste due to controlled stretch settings |

| Best Use Cases | Small businesses, low pallet volumes, flexible environments | Warehouses, logistics hubs, large-scale operations |

What is the difference between pallet wrap and stretch film?

Pallet wrap and stretch film are actually the same thing. Both names are used to describe the thin plastic film that is stretched tightly around boxes or goods on a pallet to keep them secure during storage or transport. “Pallet wrap” is the everyday name people often use in warehouses, while “stretch film” is the more technical term used by manufacturers. No matter which name you hear, they both mean the same product, a strong, stretchy plastic that protects and holds items together safely.

What Does Elongation Refer To?

Elongation refers to how much a pallet wrap can stretch without breaking. It shows how flexible the film is when it is pulled around a pallet. A higher elongation means the wrap can stretch further, which helps it hold boxes tightly together and absorb bumps during transport. Lower elongation means the film is stiffer and less stretchy, which might be better for very heavy loads that need extra support.

What is pre-stretch film?

Pre-stretch film is a type of pallet wrap that has already been stretched during the making process. Because it is already stretched, it is easier to apply by hand and needs less effort from the user. It also means you use less film to wrap a pallet, which saves money and reduces waste. Pre-stretch film is still strong enough to keep boxes and goods tightly together, but it is lighter and more efficient than standard stretch film.

Can you save money with pre-stretched film?

Yes, you can save money with pre-stretched film. Because the film has already been stretched during production, you need less of it to wrap a pallet. This means each roll lasts longer compared to standard pallet wrap. Pre-stretched film is also lighter and easier to use, which can reduce the time and effort needed to secure goods. Using less film not only lowers costs but also helps cut down on waste, making it better for the environment as well as your budget.

How does pre-stretched wrap more with less material?

Pre-stretched wrap works with less material because it has already been stretched to its maximum strength during the making process. Normal pallet wrap needs to be pulled tight while you wrap, which can waste extra layers of film. Pre-stretched wrap is thinner and lighter, but it still grips the pallet firmly because the film wants to shrink back to its original shape. This pulling force keeps the load secure without needing as many layers, so you cover more pallets using less film.

Think of it like an elastic band. If you stretch the band before you use it, it is already tight and does not need much more pulling to hold things together. Pre-stretched wrap works in the same way, holding boxes in place without wasting material.

Why is Nano film better than regular stretch film?

Nano film is better than regular stretch film because it is thinner and lighter but still very strong. It stretches further, so you can cover more pallets with less material. This means it saves money, reduces waste, and is easier to handle for hand or machine wrapping.

How does Nano film save money?

Nano film saves money because you need less film to wrap the same pallet. One roll of nano film can wrap more pallets than a roll of regular stretch film. Using less film also means you spend less on storage and shipping for the film rolls.

Is Nano film strong enough for heavy loads?

Yes, even though Nano film is very thin, it is made with special technology that makes it strong and clingy. It keeps boxes and goods tightly together during transport or storage, just like regular stretch film.

Can Nano film be used with hand wrapping and machines?

Yes, Nano film works for both hand wrapping and machine wrapping. It is easier to pull and stretch than standard film, so hand wrapping is quicker. For machines, it stretches far and holds pallets securely without using extra film.

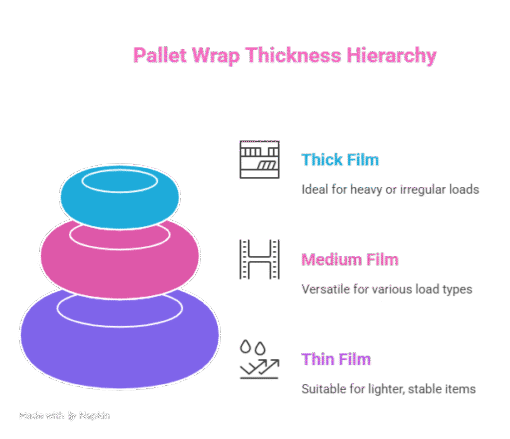

Understanding Micron in Pallet Wrap

In pallet wrap, micron refers to the thickness of the plastic film. One micron (µm) equals one-thousandth of a millimetre (0.001 mm). The higher the micron number, the thicker and stronger the film. For example, a 20 µm film is thicker and more durable than a 12 µm film. Thicker films are better for wrapping heavier or irregularly shaped loads, while thinner films are suitable for lighter, stable items.

| Product | Micron | Core Type | Colour | Length | Stretch | Ideal For |

|---|---|---|---|---|---|---|

| Megastretch Hand Pallet Wrap – 400mm x 17µm – Black | 17µm | Extended | Black | 200m | General wrapping tasks requiring discretion | |

| Megastretch Hand Pallet Wrap – 400mm x 19µm – Clear | 19µm | Extended | Clear | 200m | General wrapping tasks with visibility | |

| Megastretch Hand Pallet Wrap – 500mm x 16µm – Clear | 16µm | Standard | Clear | 200m | Warehouses and distribution centres | |

| Megastretch Hand Pallet Wrap – 500mm x 22µm – Clear | 22µm | Standard | Clear | 200m | Heavy-duty wrapping needs | |

| Machine Pallet Wrap – 500mm x 1500m x 23µm (Standard Cast) | 23µm | N/A | Clear | 1500m | Machine wrapping with standard stretch | |

| Machine Pallet Wrap – 500mm x 1500m x 23µm (250% PPS) | 23µm | N/A | Clear | 1500m | 250% | High stretch and load containment |

| Machine Pallet Wrap – Nano Film – 500mm x 10µm | 10µm | N/A | Clear | 1500m | Lightweight, high-strength wrapping | |

| Machine Pallet Wrap – Nano Film – 500mm x 12µm (300% Stretch) | 12µm | N/A | Clear | 1500m | 300% | High-speed, high-stretch operations |

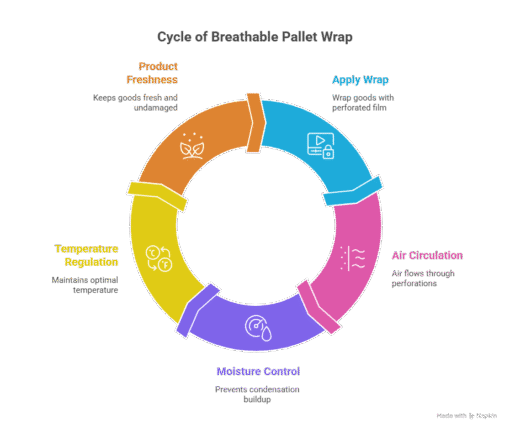

What Is Breathable Pallet Wrap?

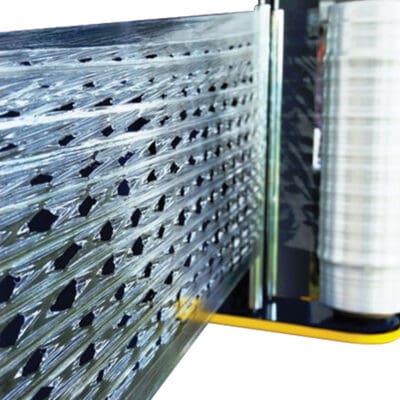

Breathable pallet wrap is a type of plastic film that has tiny holes in it. These holes let air and moisture pass through while still keeping boxes and goods secure on a pallet. Breathable wrap is useful for products that need to stay fresh or dry during transport and storage.

What is Perforated Pallet Wrap?

Perforation means the film has lots of very small holes or slits. These holes allow air to move through the wrap. Perforated wrap is another way of saying breathable wrap. The holes are so small that the pallet is still held tightly together, but the goods inside can breathe.

Breathable wrap helps control temperature and moisture around the goods. Air can flow through the holes, which stops condensation from building up. This is important for products like fruits, vegetables, flowers, or baked goods that can be damaged by too much moisture or heat.

Temperature and Moisture Control

Because breathable pallet wrap lets air in and keeps moisture at the right level, it reduces the chance of food or other sensitive products going bad. Using this type of wrap can help products stay fresh longer and reduces waste during transport or storage.

How Breathable Pallet Wrap Helps Prevent Spoilage

| Type of Product | How Breathable Wrap Helps |

|---|---|

| Fruits and Vegetables | Tiny holes let air flow and moisture escape, keeping produce fresh |

| Flowers and Plants | Air circulation maintains the right temperature and humidity |

| Baked Goods | Moisture escapes while still keeping items secure |

| Dairy Products | Breathable wrap reduces condensation and keeps temperature more stable |

| Meat and Seafood | Air and moisture control slows bacterial growth, extending shelf life |

What Is Spiral Wrap and What It Is Used For?

Spiral wrap is a strong, flexible plastic wrap that is applied around items in a spiral pattern, usually by a machine. It is used to secure long or irregular-shaped products, like pipes, timber, or cylindrical goods, so they do not move during transport. Spiral wrap helps protect items from dust, moisture, and movement while keeping them tightly together on the pallet.

Grip Pallet Wrap and What It Is Used For?

Grip pallet wrap is a type of stretch film that sticks to itself very well but does not stick to the items on the pallet. This means it holds the load tightly together without leaving marks or sticking to the boxes. It is often used for fragile, printed, or delicate items where normal wrap might damage the surface or labels. Grip wrap is great for keeping pallets stable while protecting the goods.

Can Pallet Wrap Be Recycled?

Yes, most pallet wrap can be recycled, but it depends on your local recycling rules. Clean stretch film, including hand wrap and machine wrap, can usually be taken to plastic recycling centres.

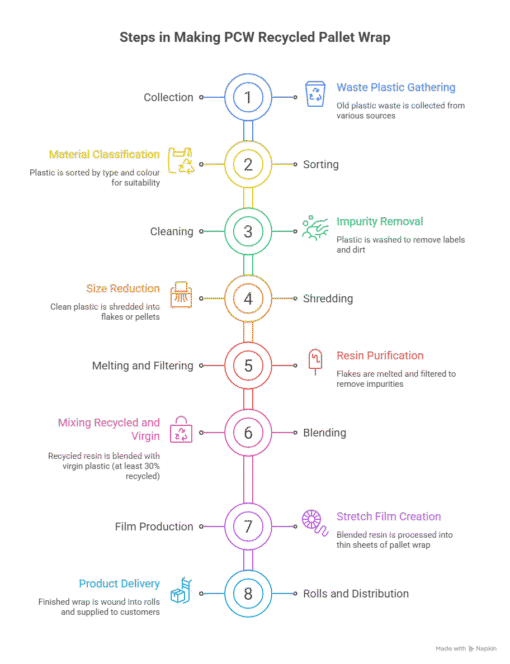

30% PCW Pallet Wrap and What It Means?

30% PCW pallet wrap is stretch film that contains 30% Post-Consumer Waste. This means that almost one third of the plastic used to make the wrap comes from recycled materials, such as old plastic bottles or packaging. Using PCW wrap helps reduce waste and is better for the environment because it reuses plastic instead of making new plastic from scratch.

Even though it contains recycled material, 30% PCW wrap is still strong, stretchy, and safe to use for wrapping pallets. It works just like normal pallet wrap but has the added benefit of being more eco-friendly.

New Innovations In Pallet Wrap

In 2023, a Melbourne-based company Great Wrap has introduced the world’s first compostable pallet wrap made entirely from food waste.

The innovative stretch film is produced using potato waste and is designed to break down naturally, providing a sustainable alternative to conventional plastic wrap.

To further scale its impact, Great Wrap plans to open a dedicated biorefinery by 2025, with the goal of producing up to 20,000 tonnes of PHA – a marine-degradable material that can help reduce plastic pollution in oceans and landfills.

A new study published in Cleaner Environmental Systems has also found that polyethylene (PE) packaging, which includes pallet wrap, can have a lower global warming impact compared to alternatives such as paper, metal, and glass.

By examining the full life cycle of different packaging materials, the research shows that PE often performs better in terms of overall emissions.

These findings underline the importance of assessing packaging options based on their complete environmental impact rather than on assumptions about material type.

Summary

Pallet wrap can be applied by hand or machine. Hand wrap is lighter and easy to pull. Machine wrap is stronger, stretches further and works best for busy warehouses that wrap many pallets. Pre-stretch film is a type of pallet wrap already stretched during production. It uses less material, saves money, and is easier to apply. Nano film is very thin but strong. It stretches further, covers more pallets with less material and reduces waste.

Special types of pallet wrap include breathable or perforated wrap, which allows air to pass through. This helps keep fruits, vegetables, flowers and baked goods fresh. Grip film sticks to itself but not to boxes, protecting fragile or printed items.

Sustainability is growing in importance. 30% PCW pallet wrap uses recycled plastic from bottles or packaging. It is strong, stretchy and safe, while helping reduce waste. Companies like Signode also make PCR pallet wrap, which uses high-quality recycled materials including used stretch film. These eco-friendly pallet wraps support the circular economy, cut costs and reduce environmental impact.

Struggling to Find the Right Packaging Solution?

Let Hub Packaging help you find the right solution. Our dedicated customer service team is here to support you!

📞+44 (0)28 4175 4977

📧 sales@hub-packaging.com

We’re here to make packaging work better for your business.